Sustainable steel manufacturing

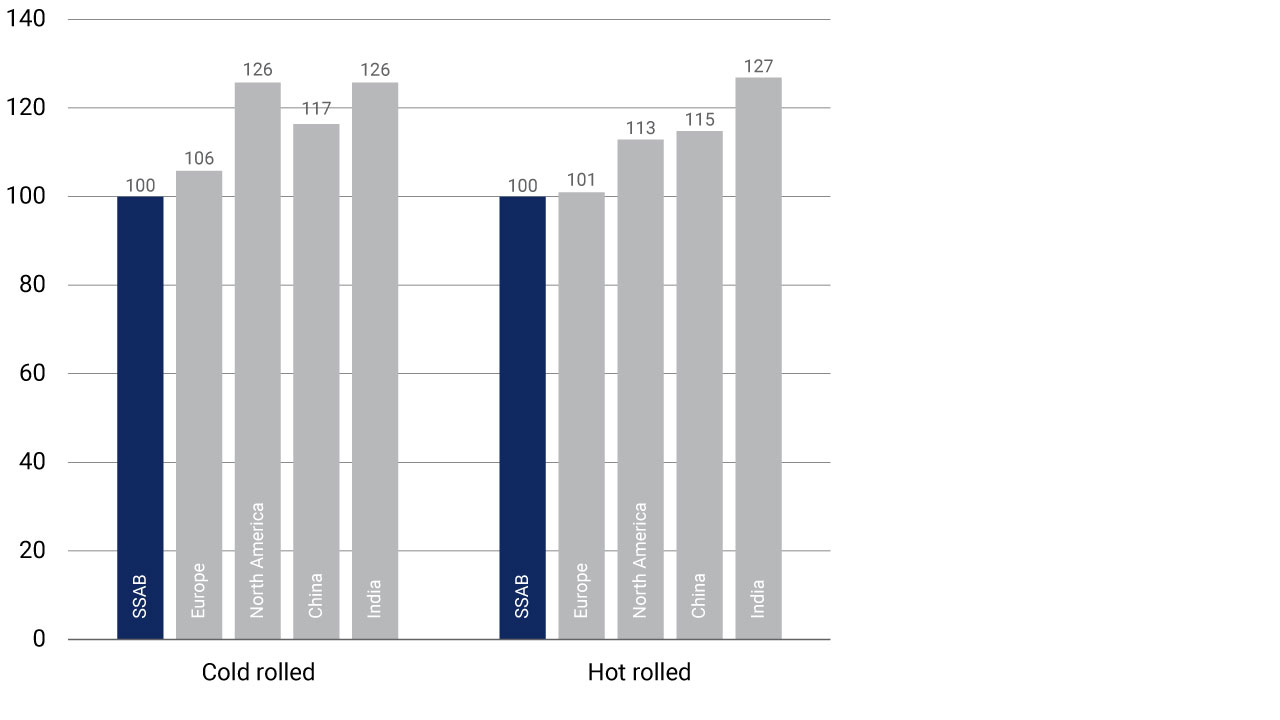

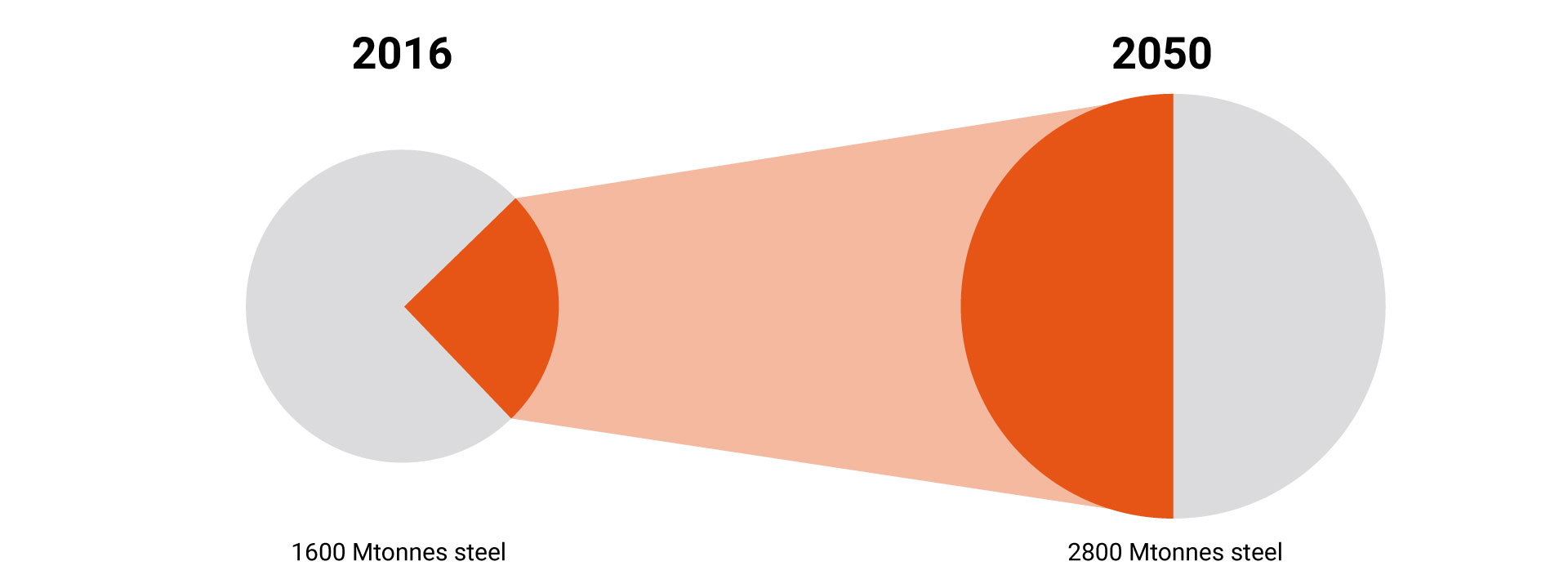

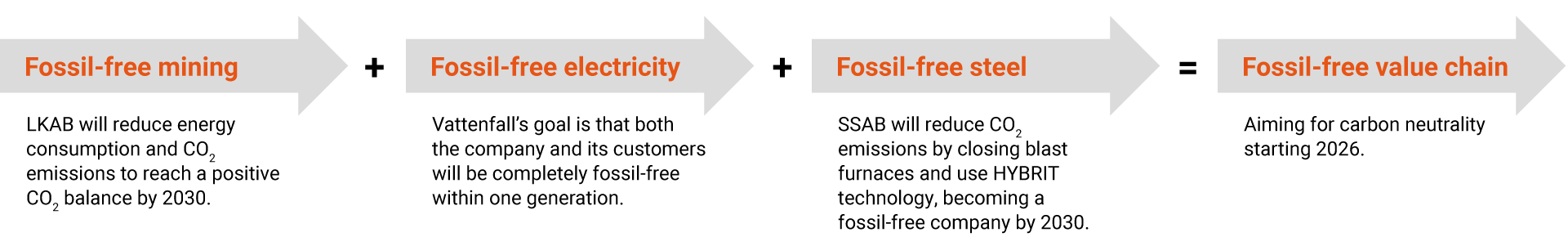

Raex® steel is manufactured by SSAB and sold through the global Raex® distribution network. The steel industry is currently one of the highest CO2 emitters, accounting for 7% of all emissions globally. Today, the CO2 efficiency level at our plants is one of the best in the world regardless of geography. But we are determined to continue our efforts to decarbonize the steel industry, and Raex® is part of this goal. So far, SSAB is the only steel producer that has committed to and is investing in a completely fossil-free value chain including steel production. The first fossil-free steels will be commercially available to customers after 2026 and fully implemented in 2030.

English (English)

English (English) Finnish (Suomi)

Finnish (Suomi) French (Français)

French (Français) German (Deutsch)

German (Deutsch) Italian (Italiano)

Italian (Italiano) Polish (Polski)

Polish (Polski) Spanish (Español)

Spanish (Español) Swedish (Svenska)

Swedish (Svenska) Turkish (Türkçe)

Turkish (Türkçe)